Sustainable heat and power

The EU, as well as many other countries, have put district heating on the agenda with their climate goals. Proper water treatment is a precondition for optimum return on investment, since correct water quality is essential for optimizing the life cycle of pipes, boilers and heat exchangers.

Boilers and turbines for heat and electricity production are highly sensitive to corrosion, deposit and scale caused by dissolved salts and particles in the water. Removing of these elements is essential for operation, service life, and security of supply.

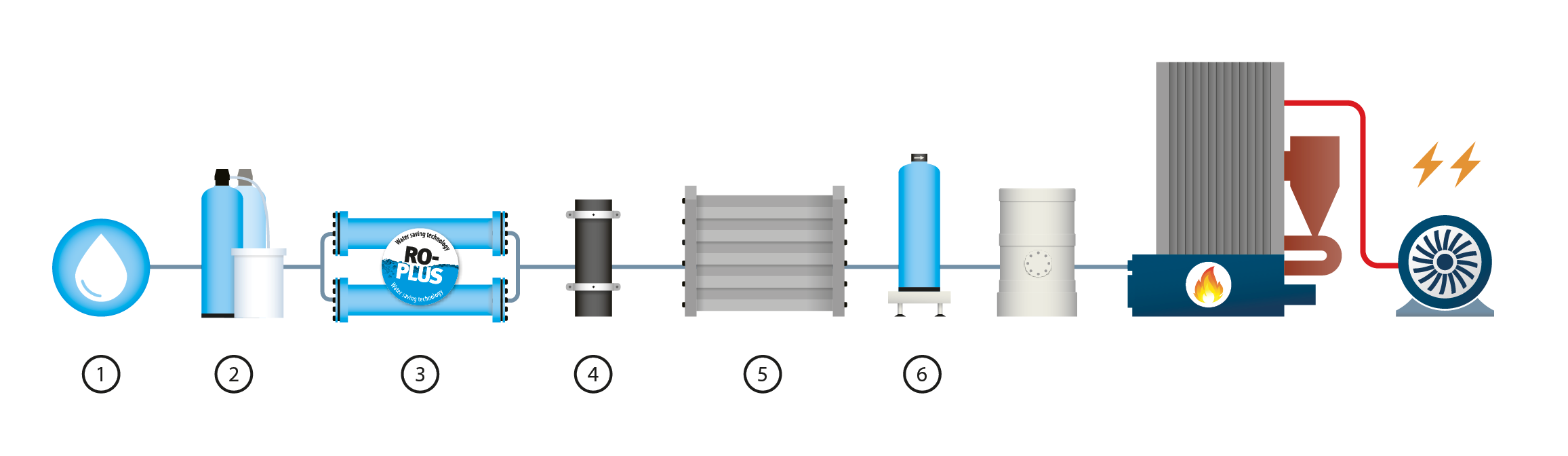

1. Drinking water

Reduction of iron and manganese content in a pressure filter, provided that the inlet water is not of drinking water quality.

Removal

Iron (Fe++)

Manganese (Mn++)

2. Softening

Softening by ion exchange as pre-treatment to the reverse osmosis system.

Removal

Calcium (Ca++)

Magnesium (Mg++)

3. Demineralization

Demineralized water by reverse osmosis. 98-99% salts are removed.

Removal

Potassium (K+)

Sodium (Na+)

Chloride (CI-)

Nitrate (NO3-)

Sulphate (SO4--)

Silicic acid (SiO4-)

Alkalinity (HCO3-)

4. Degassing

Removal of oxygen using a membrane degasser or a vacuum deaerator.

Removel

Carbon dioxide (CO2)

Oxygen (O2)

5. Ultrapure demineralization

Ultrapure demineralization by EDI

Removel

Residual salts

6. Polishing

Polishing of the ultrapure water by a mix-bed unit. Security for removing residual salts and silicic acid.

Ultrapure water without chemical use

At Energie Steiermark Power Plant in Graz, Austria, the water treatment plant consists of two independent lines with double-pass reverse osmosis, membrane degasser, and EDI producing ultrapure water.

This solution provides demineralized water without using any chemicals, which ensures minimal environmental impact.

Ultrapure water by ion exchange

The Danish energy company Verdo provides electricity for 32.000 recipients and district heating for 10.500 customers. Their makeup water treatment is based on the UPCORE™ technology and used for a high-pressure steam boiler.

The UPCORE™ principle ensures an efficient use of the regeneration chemicals and combines all the known advantages of ion exchange demineralization with the counter-flow principle.

Plug and play

Individual units can be frame mounted for a complete and compact solution, ready for use. It also allows for pressure testing, functionality testing and Factory Acceptance Testing (FAT) before delivery.

The solution is complete with all internal piping and wiring factory-built. The whole plant has been performance and pressure tested in our factory. This safety can be achieved with a EUROWATER frame-mounted plant or a container-installed plant.

Optimum water treatment for heat & power plants

In this leaflet we put water on the agenda! Learn how to reduce corrosion and wear of boiler by providing optimum make-up water for high-pressure boilers. Water treatment for District Heating is also covered.

How can we help?

Our team of specialists are ready to answer your questions about pure water treatment solutions.