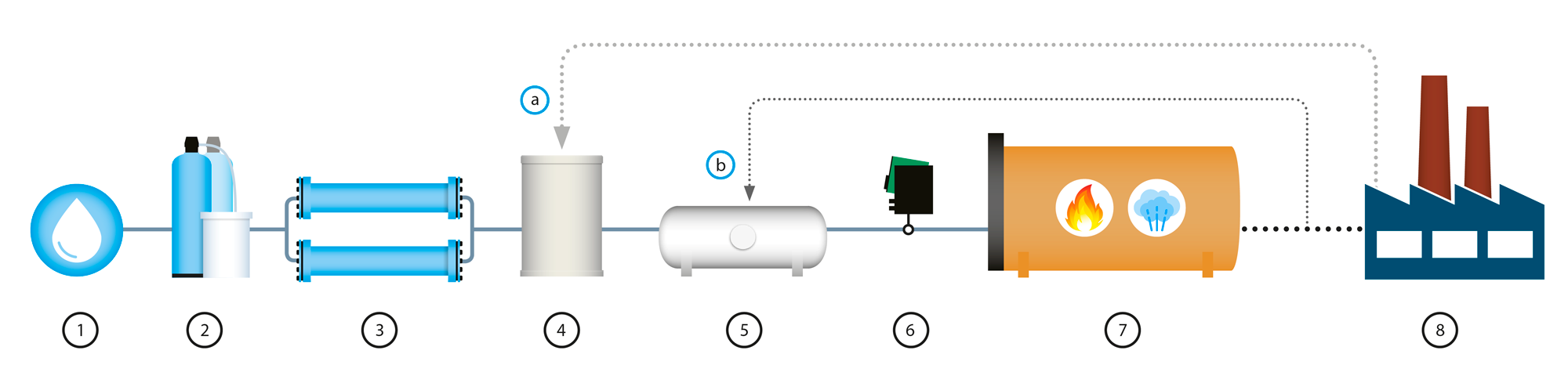

The optimum solution for industrial boiler water treatment

To sustain high-purity feedwater and make-up water flow, an optimum boiler water treatment system primarily consists of pressure filter, softening plant, reverse osmosis unit and thermal deaerator.

The use of common hard mains water as make-up water for a steam boiler will cause precipitation of lime stone on the boiler heat area. Thus, increases the energy loss and the amount of acid for cleaning the boiler inside.

By softening the water, scaling is prevented but the content of bicarbonate of the raw water passes the softening plant without hindrance. In the boiler the bicarbonate splits into carbon dioxide (CO2) and sodium hydroxide (NaOH) creating corrosive condensate and increase the need for blow down. The problem can be avoided by removing the salt content of the make-up water in a reverse osmosis plant or in a two-column ion exchange plant to get demineralized water and then degassing with a thermal deaerator.

1. Raw water

Pressure filtration of raw water.

Removal

Iron (Fe++)

Manganese (Mn++)

2. Softening

Softening by ion exchange.

Removal

Calcium (Ca++)

Magnesium (Mg++)

3. Demineralization

Demineralized water by reverse osmosis.

Removal

98 % salts

Potassium (K+)

Sodium (Na+)

Chloride (CI-)

Nitrate (NO3-)

Sulphate (SO4--)

Silicic acid (SiO4-)

Alkalinity (HCO3-)

4. Water tank

Storage of the demineralized water.

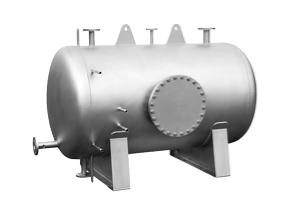

5. Degassing

Removal of gasses with a thermal deaerator.

Removal

Carbon dioxide (CO2)

Oxygen (O2)

6. Dosing pump

Pump for dosing of chemicals to maintain boiler operation.

7. Steam boiler

The water is heated to create high quality steam.

8. Production

Condensed water is lead to the water tank (a). Steam for preheating is lead to the thermal deaerator (b).

Minimize boiler blowdown and save water and energy

Blowdown of steam boilers is necessary to comply with the specifications of the boiler suppliers as to the contents of salt (specific gravity) and the alkalinity (P-value) in the boiler water. The volume of blowdown is determined by the boiler type, operating pressure and water treatment quality of feed and makeup water.

In high quality boiler water, levels of suspended and total dissolved solids (TDS) are down to a minimum. This will minimize blowdown volume and hereby reduce energy loss, as the temperature of the blowdown liquid is the same as the steam generated in the boiler. Lower blowdown rate will also reduce makeup water and chemical use, saving you money and water.

Product inspiration

Degas to minimize corrosion

Dissolved oxygen is highly corrosive and is one of the unwanted impurities to consider when choosing correct makeup water treatment for industrial steam boilers. Since softening and demineralization do not reduce the partial pressure of gases, the water will often be saturated with oxygen from the waterworks.

Dealkalizers

Alkalinity of the water is an essential factor when producing goods within food, beverage and textile industries and even more so in boiler operations. Through dealkalization the bicarbonate hardness is reduced, thus typically reducing the salt content in the water by approximately 75%.

Reference

Water waste reduced by 75 %

Arla, the largest food company within dairy products in Denmark, has reduced their water waste by more than 75 % with the RO-PLUS technology from EUROWATER. Demineralized water is used as makeup water for steam boiler, laboratory use, and internal cooling on filling machine. The amount of water recovery also reduces their consumption of salt and energy and lower the operational cost.

How can we help?

Our team of specialists are ready to answer your questions about pure water treatment solutions.