Bag filter for mechanical filtration

Bag filters are ideal for filtration jobs with heavy demands on flow rates and space. They are typically used for filtration of both boiler and cooling water, circulation water in district heating plants, rinse water and process baths in the surface treatment industry and in the electronics industry.

The bag filters have a robust design, which makes them suitable for both cold, hot, acid and basic liquids. They are easy to install and maintain and have no rinse water consumption.

Filter bags for a wide range of applications

Where bag filters make a difference

As a prefilter or partial flow filter, a bag filter can serve many purposes. Here are some examples of the applications that can benefit from mechanical filtration.

Filtration of district heating water

The circulation water in district heating plants should not contain sludge and mechanical impurities, because they cause corrosion and clogging of the regulating equipment. A bag filter for hot water is suitable for partial stream filtration. The EFG5 type filter is designed especially for district heating plants.

Filtration of process baths

In surface treatment industries, a bag filter can ensure clean process baths which prolong the tool life. Special filter bags designed for degreasing and phosphating baths prolong the life of the bath, thereby reducing the quantity of waste water and the risk of clogging the nozzles and the valves in the system.

Protection of membranes

All water supplies contain organic matter. Prefiltration is therefore relevant in the water treatment process to protect and extend the lifetime of other water treatment units such as reverse osmosis plants.

Optimum filtration with magnetic insert

The magnetic insert is efficient for capturing small magnetic particles, typically not retained by a filter bag.

A partial stream filtration using magnets is particularly useful for circulating water, e.g. district heating plants, where magnetite naturally forms in the circuit water.

The top fits all existing EUROWATER bag filters, making an upgrade easy and affordable compared to changing the entire unit.

Contact us for more information

Case

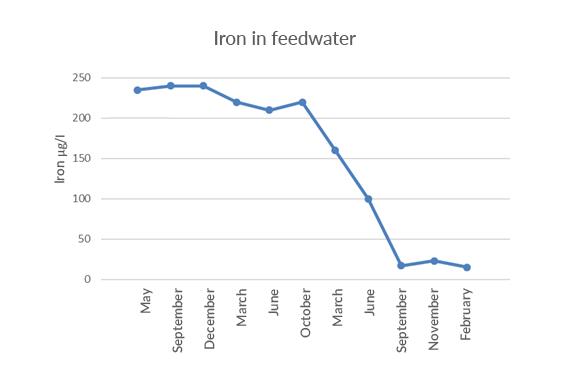

Reduction of iron in feedwater with magnetic insert

The Danish district heating company Hvide Sande Fjernvarme, had a high level of iron in the feedwater. Production manager, Martin Kristensen, explains:

"We had to do something about the iron content in the water, because it was above the recommendations of the Danish District Heating Association of 100 µg / L. We tried a 1 micron filter in a partial stream plant with two bag filters and a magnetic insert. It seemed to work!"

Reduction of iron in the district heating system, is part of asset management. Risk of corrosion in boilers, valves, fittings, installations, and underground piping is reduced significantly.

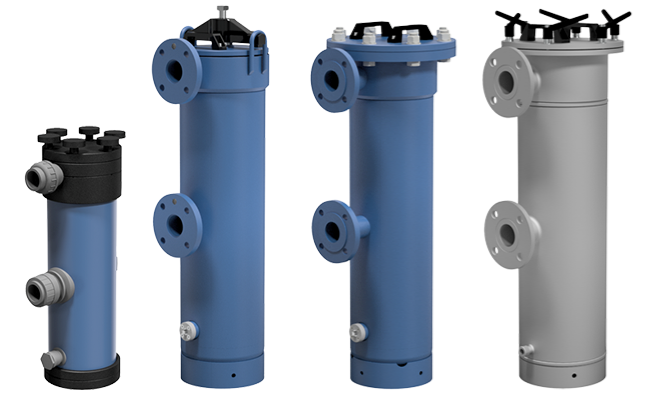

Product overview

Our product range comprises a wide number of standard plants, all engineered and manufactured in-house. The starting point is our modular-built standard system ensuring high flexibility, high operational reliability, and short delivery time. Each solution can be customized and built according to the specific application needs by carefully combining materials, instrumentation, and control systems.

Plant design

A bag filter consists of a filter house with cover and a support screen for the replaceable filter bag. The filter house is available with different surface material on the inside and outside according to filtration task.

Contact your local sales and service office for more information and request of data sheets and instructions.

Flow rate up to 12 m3/h

| Product type: | EF2 |

| Max. operating pressure: | 6 bar |

| Max. temperature: | 35 oC |

| pH range: | 1-13 |

Flow rate up to 22 m3/h

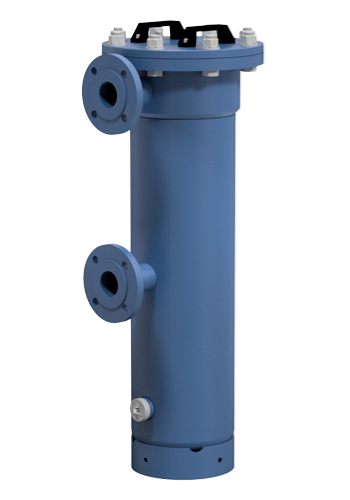

| Product type: | EF5/EFG5 |

| Max. operating pressure: | 6 bar |

| Max. temperature: | 100 oC |

| pH range: | 1-13 |

Flow rate up to 22 m3/h

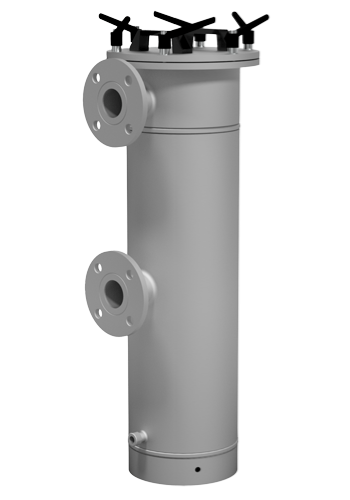

| Product type: | EFG7 |

| Max. operating pressure: | 16 bar |

| Max. temperature: | 100 oC |

| pH range: | 7-13 |

Flow rate up to 22 m3/h

| Product type: | EFG8 |

| Max. operating pressure: | 6 bar |

| Max. temperature: | 100 oC |

| pH range: | 7-13 |

A selection of frame-mounted units

The bag filters are also available as frame-mounted units

with optional pump and with two or more bag filters for higher flow rates.

EFG5P-F - Bag filter unit

- Flow rate up to 22 m3/h

- 1 bag filter

- Welded pipe system

- Pressure gauges

- Pump

2-EF5-F - Bag filter unit

- Flow rate up to 44 m3/h

- 2 bag filters

- PVC pipe system

- Pressure gauges

- Stop valves

2-EFG7P-F - bag filter unit

- Flow rate up to 40 m3/h

- 2 bag filters

- Welded pipe system

- Pressure gauges

- Pump

Customized

High flow rate

Filter bags can be combined in series to obtain a high flow rate. The photo shows an installation with 10 bag filters type EFG7 at a district heating company in Germany.

Learn more about bag filtration

Download our leaflet to get more information about our bag filter systems.