Plug-and-play water treatment

ensures quality and reduces installation time

Published: 8 September 2020 | Contact

When installation time and quality have top priority, a factory-built solution could be the right choice. That was exactly the case for a Romanian manufacturer of spirits.

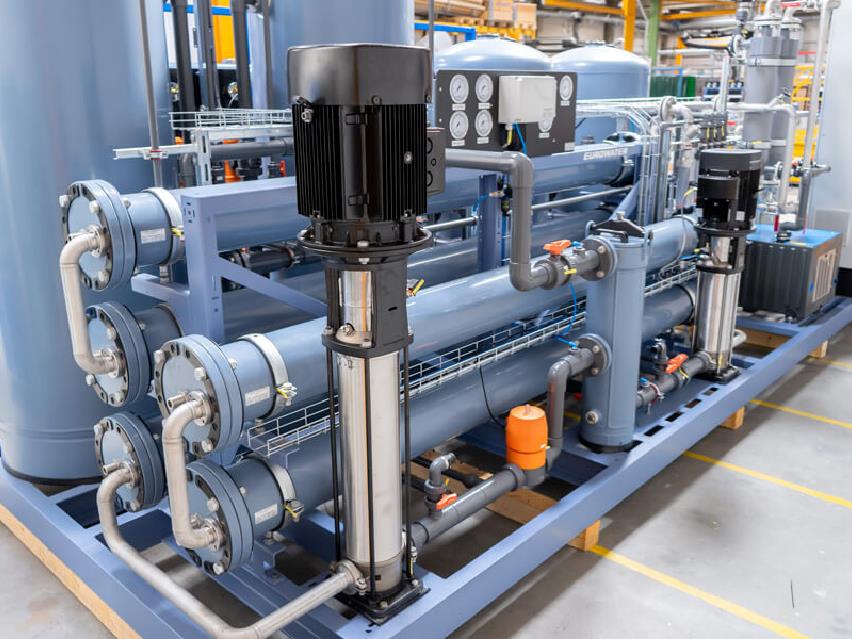

A water treatment solution consists of several treatment steps - filtration, softening, membrane filtration, booster pumps – all controlled from a central control cabinet. Basically, two approaches can be used when installing such a solution.

- The water treatment units and components are delivered individually and assembled on site.

- A factory-built system where all units and components are installed on a frame or skid; the “plug-and-play” approach.

The plug-and-play approach offers several advantages:

- Factory-built systems allow parallel construction, reducing installation time on site.

- Off-site construction eliminates interference with facility production.

- A single-source design comprises all necessary system components, including process piping and wiring, and ensures proper system functionality and component dimensioning.

- Assembly takes place under ideal workshop conditions with full access to testing and manufacturing equipment as well as knowledge centres.

- Fewer on-site contractor manhours reduces risk of safety incidents.

- Testing is done before shipment.

- Straightforward connection to existing process equipment.

Read more: Frame-mounted water treatment plants - ready for use!

Customer case

Alexandrion, a Romanian brandy manufacturer chose a plug-and-play solution. The complete water treatment system was assembled at the EUROWATER production facility in Denmark. Upon completion and testing, the entire solution was shipped to the customer location, where it was installed. This was managed by the local EUROWATER distributor in Romania, Hydro-X.

“The installation time was very short. From placing the two frames on site, it only took two days to make piping and electrical connections between the frames and tying it into the existing process. The plant produced high water quality from the start.”, says Florian Radu, Managing Director of Hydro-X.

1. Filtration

Removal of iron and manganese from groundwater in automatic pressure filters.

2. Activated carbon filter

Activated carbon filters remove colour, taste and odour from the water and serve as an extra safety precaution.

3. Softening

Softening unit for reducing the hardness in the water and preventing calcium deposits in the subsequent membrane filtration unit.

4. Reverse osmosis

Two reverse osmosis units (double-pass RO) are connected in series so the second unit treats the permeate from the first unit.

5. Membrane degassing

The membrane degassing unit (MDU) provides an efficient and chemical-free technology for removing CO2 from the RO permeate.

6. EDI

The EDI unit is used after the RO system for polishing of demineralized water to obtain low levels of conductivity.